LAYOUT

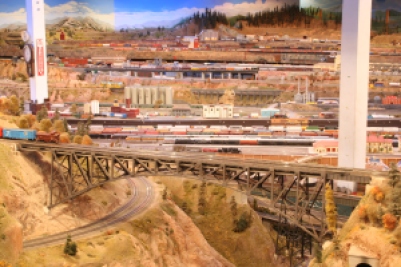

Type: Point-to-point, single track with passing sidings

Type: Point-to-point, single track with passing sidings

Main line length: 1,700 feet (approximately 28 scale miles)

Passing siding length: 30 to 60 feet

Tunnels: 25

Bridges and trestles: 33

Time to run end-to-end: Approximately 1 hour for fast passenger/express trains

GRADES AND CURVES

Ruling grade: 1.5%

Maximum grade: 2%

Minimum curve radius (main line): 42 inches

TRACKWORK

Type: Hand-laid (including turnouts)

Rail: Code 100 steel, approximately 30,000 feet

Ties: Hand-stained, approximately 500,000

Turnouts: #8 minimum, approximately 400

YARD CAPACITY

YARD CAPACITY

Alhambra: 850 cars

Midway: 550 cars

Zion: 600 cars

CONTROL SYSTEM

Rails/DCC :

- Digitrax DCS-240 with multiple Digitrax boosters

- Digitrax 400/500/600 series plug in and wireless throttles primarily with UT-4’s for basic train operation

- Every major mainline block and each self sufficient significant geographic non-mainline or yard area is individually PSX protected

Non Rail:

- The DC to Digital conversion was started when LCC (Layout Command Control) was still in its early infancy. Although the technology was closely followed as it solidified, we did not start incorporating it until after the 2018 NMRA National convention in Kansas City., approximately ½ way through the conversion. At that point forward all conversion of the non-rail control items were solely put on LCC

- The majority of the four track eastern mainline and the western single track main line turnout control and detection are on Digitrax, Loconet and RR-CirKits Loconet compatible gear

- LCC primarily looks after all of the three large yards and complex multi-track yard throats including all turnouts, track power control (we turn on and off yard tracks individually to keep sound levels reasonable, among other reasons), and physical control panels. There are other smaller areas of LCC but those are the key parts.

- More LCC is being added, limited only by time and effort constraints

- The LCC was implemented as 6 distinct and self contained/terminated LCC islands: Alhambra Freight West, Alhambra Passenger West, Alhambra Freight/Passenger East, Engine service, Midway and Zion which were tied together, without issue, into a single large network in 2021. This segregation into these geographically separate areas wasn’t because of any concern about LCC per se but rather convenience dictated by the physically large size of our layout as the LCC sections are at the extreme ends and middle of the approximately 1700’ point to point mainline as they are the East Coast, Midway (start of mountain district, say ‘Denver’) and West Coast yard areas and there was no initial driving need to connect them to each other given the strong core LCC architecture and independence

- We currently have 31 Towers and 2 Signal LCC nodes in service and 1 Gateway to transcribe the Loconet to LCC and back when appropriate. All LCC gear is RR-CirKits

- Key hard panels from the original layout have been either modified to LCC or revamped from the base metal (quite literally) up from scratch to be LCC or LCC/hybrid. This really minimizes the technology learning curve for complex operating positions and invokes strong nostalgia of the incredibly robust and time proven panel designs of the DC layout

- Soft and virtual control panels are also used for local control both as Rasberry Pis connected directly to LCC and as remote virtual Wi-Fi connected tablets or Pis via the primary JMRI dispatching computer

- JMRI Panel Pro is used for end-to-end dispatching with RR&Co’s as an option

- The JMRI dispatching computer only connects to Loconet, with the LCC needed information presented via the Gateway to Loconet to JMRI and vice versa